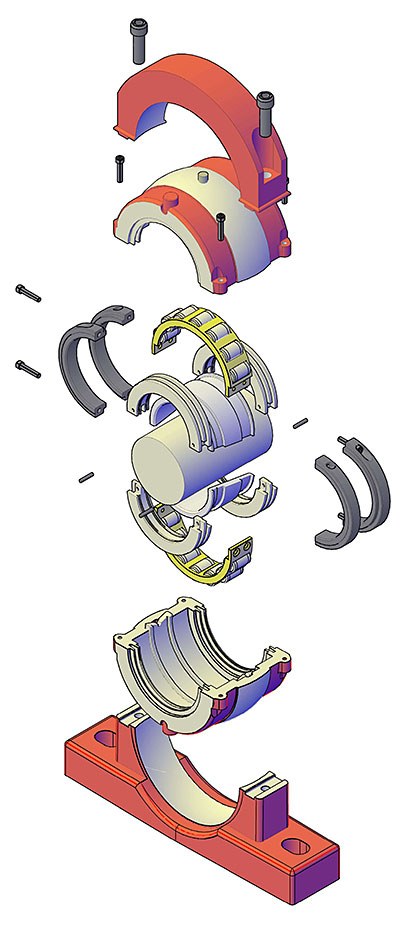

CRAFT SPLIT ROLLER BEARING

With thousands of applications around the world, there is a bearing for what you need. Find out if Craft’s Split Bearing is for you.

Under Construction

Please pardon our mess as we tidy up a bit.

Call us today at 757-247-6000 or Email us at info@craftbearing.com

The Split Makes the Difference.

The Craft Split Roller Bearing

The Craft Split Bearing is quickly becoming the global industry standard for its exceptional reliability and easy replacement. From mining operations to paper mills, marine applications to steel production, this innovative design turns potential catastrophic failures into routine maintenance. Proudly manufactured in the U.S.A. at our Newport News, Virginia facility, it meets the demands of heavy industry worldwide, delivering dependable performance and reducing downtime wherever it’s installed.

- Split to the shaft construction – for ease of installation and maintenance.

- Made in the USA – designed, manufactured, warehoused in Newport News, Virginia.

- Self-Aligning – the bearing cartridge and housing externally self adjust to handle up to 3 degrees of misalignment, as standard.

- Manufactured of through-hardened 52100 bearing steel (rollers, inner and outer races).

- Ductile iron standard – Cartridges, pedestal, and flange housings are machined from high strength 65-45-12 ductile iron and steel is available upon request.

- Powder coat finish for all cast parts – cartridges, housings, and flanges

- Drain plugs – on cartridges to allow purging of grease.

- Socket head hardware – SAE standard, grade 8.

- Triple labyrinth seals – Feature dovetail groove design to fully retain the O-ring material, allowing the seal to rotate with shaft to avoid shaft wear and provide superior sealing.

- Patented roller cage – The roller cage has cylindrical pockets that encapsulate the rollers and maintain an even spacing between rollers. Small sizes feature “Zamak 3” or aluminum. The cage performs as a one-piece cage when installed.

- Bronze roller cages – From 4” and up in the S1 series, and all S2 and S3 series bearings, the cages are made from 932 bearing bronze. These cages are assembled with a bolted lap joint and utilize high tensile Nylock screws.

- Economic advantage – Higher quality and longer life.

- Float (expansion) and held (non-expansion) bearing are the same price.

- Three progressively heavier duty groups – S1, S2, and S3 series to best suit load, life, and speed requirements.

- Most sizes are available from stock for immediate shipment – Normal inch sizes (1-7/16” – 12”) and metric (40 mm – 300 mm) are in stock. Larger sizes to 32”, and special designs are available upon request.

- Cylindrical bore bearings – “Straight from the shelf” standard shafting can be used, greatly reducing costs in machine design, construction, and maintenance.

- Custom work – special application bearings, housings, and cartridges are available upon request.

- Lloyd’s Register Type Approved and U.S. Dept. of Defense Approved.

- Full factory support.

- Supported by our ISO Quality Certification

Market Applications

Here are prime examples of markets where the Craft Split Bearing makes a powerful difference.

Mining / Aggregate

Coal, copper, zinc, silver, gold, mining, cleaning, processing, general mineral extraction, fans, conveyors, bucket elevators, haulage gearing, crushers, pulverizers, flotation cells, ball and rod mills, reciprocating screens, pinion gears, pug mills, pulleys, winch drums, cranes.

Food Processing

Bottle washers, canning machines, steamers & cookers, steam peelers, cereal dryers, fans, hammermills & grinders.

Pulp and Paper

Mixers, conveyors, agitators, fans, log decks, chip conveyors, calendar and press rolls, paper drying cylinders, re-winders, line shafting, hydra-pulpers, de-barkers.

Power Generation

Ball mills, fans, belt conveyors, crushers, pulverizers, breakers, generator sets, pumps, horizontal and vertical hydro generators, screens, dampers.

Iron and Steel

Coal crushers, drag conveyors, roll out tables, cooling beds, transfer beds, mill drives, cranes, bag house fans, primary air fans, charging car conveyors, bucket elevators, coilers, fans, loaders, plating.

Cement Production

Clinker crushers, clinker coolers, conveyors, fans, elevators, bucket elevators, kiln drives, ball mill drives.

Marine

Fans, propulsion shafting, bow thrusters, gearboxes, winches, rudder stocks, deck machinery, inert gas fans, conveyors systems. (For high speed & double ender ferries, tug and and tow boats, fishing vessels, ore carriers, pilot boats, fire boats.)

Lumber

Dry kilns, log decks, chain and belt conveyors, fans, chipboard, and plywood veneer plants.

Water and Waste Water Treatment

Paddle wheel and rocker arm mechanical flocculators, rotary and disc aerators, RBC’s, CBC’s, tank scrapers, rotary screen, sludge presses, conveyors, fans.