Craft Split Bearings: Reduce Downtime, Save Costs, and Boost Efficiency

Easy Installation and Inspection

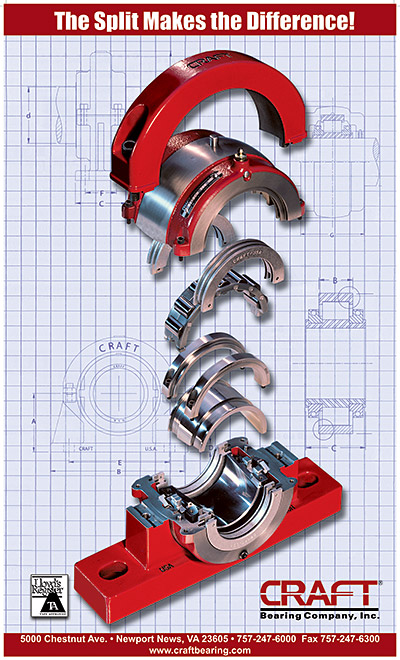

Craft Split Bearings feature conventional cylindrical roller bearing benefits, plus the ability to assemble around a shaft. Each bearing is engineered in halves, so you can install, inspect, or replace them without disturbing nearby equipment or realigning components. All you need are simple, inexpensive hand tools.

Efficient Machine Design

Because Craft split bearings use standard straight shafts, you can eliminate costly special machining, tools, and procedures. This streamlined approach reduces complexity in machine design.

Reduced Downtime and Costs

Maintenance, downtime, and lost production are minimized throughout the bearing’s lifecycle. These savings go straight to your bottom line, making Craft split bearings a cost-effective solution.

Reliable Performance

Every Craft split bearing is made with high-quality materials and meticulous manufacturing processes, ensuring long-lasting performance.

Flexible Sizing

Available in both inch and metric bores, with special sizes offered on request for fast turnaround.

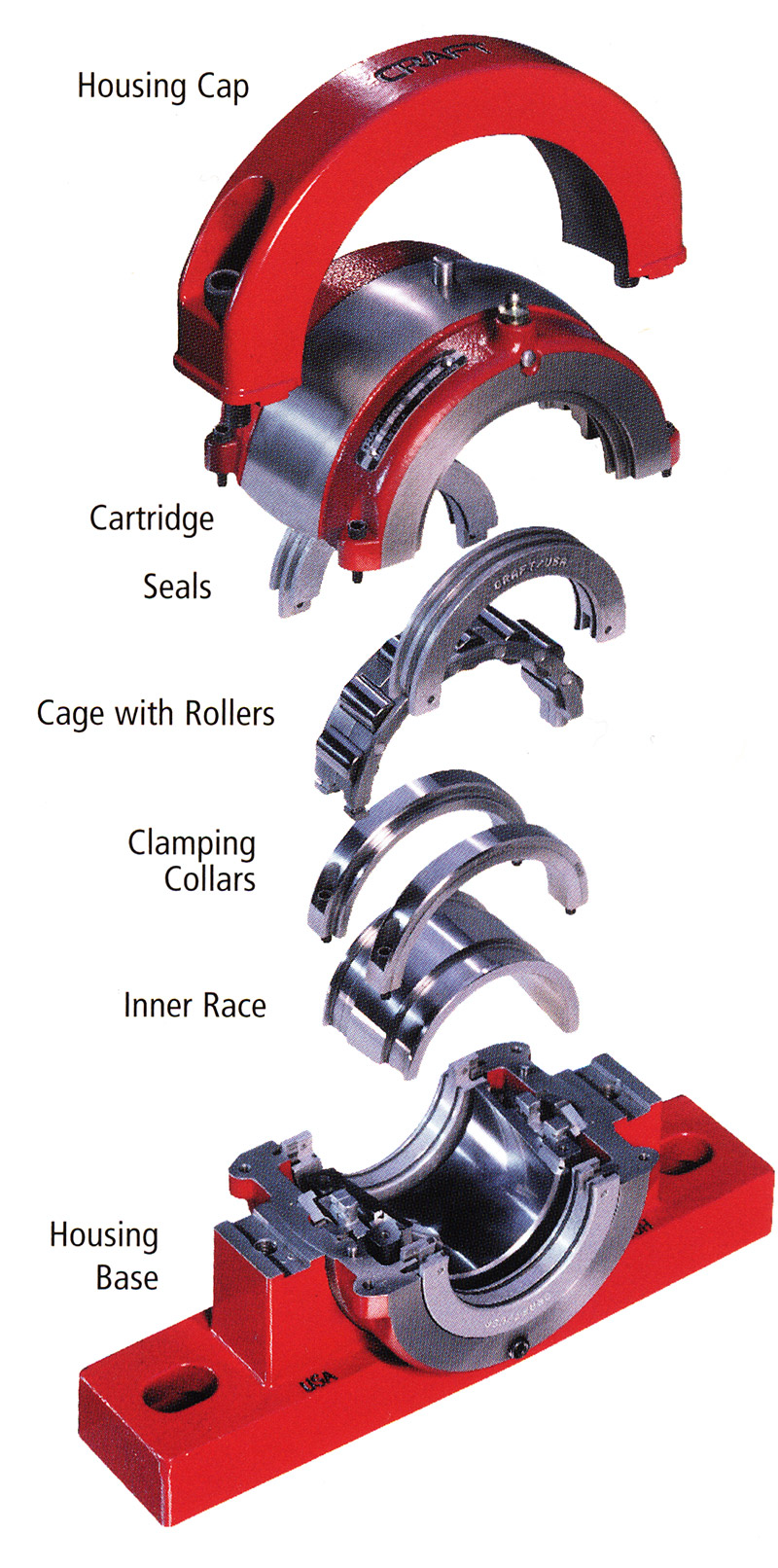

Bearing Features

Our Craft Split Bearings are built to excel across a wide range of applications and environments, delivering top-tier durability and ease of use. Below is a snapshot of the key features that set them apart—from our split-to-shaft construction for straightforward installation to our U.S.-made quality and broad size availability. Explore each detail to see how Craft Bearings can optimize your operation and lower costs over the long haul.

- Split-to-Shaft Construction: Eases installation and maintenance.

- Made in the USA: Designed, manufactured, and warehoused in Newport News, VA.

- Self-Aligning: Cartridge and housing handle up to 3° of misalignment.

- Through-Hardened 52100 Bearing Steel: Rollers, inner, and outer races.

- Ductile Iron Standard: Cartridges, pedestals, and flanges machined from high-strength 65-45-12; steel available on request.

- Powder-Coated Finish: Applied to all cast parts—cartridges, housings, flanges.

- Drain Plugs: On cartridges for grease purging.

- Socket Head Hardware: SAE standard, Grade 8.

- Aluminum Triple Labyrinth Seals: Dovetail groove design retains the O-ring, allowing seal rotation with shaft to avoid wear.

- Patented Roller Cage:

- Smaller sizes use “Zamak 3” (zinc alloy).

- Cylindrical pockets encapsulate rollers for even spacing.

- A tongue-and-groove joint with a spring clip creates a one-piece cage when assembled.

- Bronze Roller Cages:

- For 4″ and up in S1 series; all S2 series use 932 Bearing Bronze.

- Bolted lap joint secured with high-tensile Nylock screws.

- Economic Advantage: Higher quality for longer life.

- Float & Held Bearings: Same price in all sizes.

- Three Duty Groups (S1, S2, S3): Match load, life, and speed requirements.

- Broad Size Availability:

- In stock for quick shipment: Inch (1-7/16″–12″) and metric (40 mm–300 mm).

- Larger sizes up to 32″ and special designs available on request.

- Cylindrical Bore Bearings: Standard “off-the-shelf” shafts reduce design, build, and maintenance costs.

- Custom Work: Special bearings, housings, and cartridges on request.

- Approvals: Lloyd’s Register Type Approved and U.S. Dept. of Defense Approved.

- Full Factory Support: Backed by our expert team.

Warranty

Craft Bearing Company, Inc. will replace or repair any part or parts of Craft’s bearings that fail due to defective materials or workmanship that are returned to its factory within one year of delivery to the original purchaser. This constitutes Craft’s only warranty in connection with the sale, is in lieu of all other warranties, expressed or implied, oral or written, and Craft shall have no responsibility for consequential or other damages. No employee, distributor, or agent is authorized to give any other warranty on behalf of Craft.

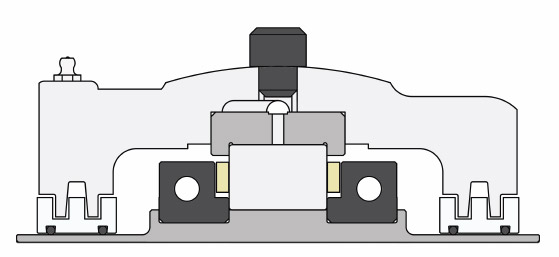

Standard Components

Craft Split Bearings offer the same advantages as conventional cylindrical roller bearings, plus an easy-to-assemble, split design. Engineered in halves, they simplify installation and inspection while minimizing the need to move or realign adjacent equipment. All you need are standard, inexpensive hand tools.

By allowing the use of standard straight shafting, Craft Split Bearings eliminate costly special machining and reduce design complexity. Maintenance, downtime, and lost production costs are significantly lower over the lifetime of your equipment—boosting your bottom line.

Careful attention to design, materials, and manufacturing ensures the long-term reliability of Craft Split Bearings. They are available in both inch and metric sizes, with special and one-off options offered on a quick turnaround. These core features highlight how Craft Split Bearings can optimize your operations.

Specialty Components

Extended Inner Race

Craft Bearing’s Split Bearing standard ATL seals eliminate shaft wear and provide excellent sealing in most applications. In extreme conditions, however, shafts may be grooved or rough from prior bearings with lip seals that cut into the surface. Abrasive contaminants can also infiltrate under O-rings, damaging the seals or shaft.

Craft’s extended inner race (patent pending) is ideal when a damaged shaft or extreme conditions would normally require repair or replacement. Lengthened under the seal and equipped with a machined track, the seal clamps to the inner race instead of the shaft—eliminating issues from grooves or roughness caused by conventional bearings and preventing further shaft damage.

The shaft must still be clean, round, within tolerance, and free of high spots. The extended inner race covers typical grooves, rough surfaces, and gouges left by previous bearings. Contact our technical department with any questions.