Select The Correct Bearing

Craft Bearing Series

Craft Bearing offers three bearing series:

S1 (Standard Duty)

S2 (Heavy Duty)

S3 (Extra Heavy Duty)

They carry standard stock bearings from 1-1/2 to 12 inches (or equivalent metric sizes). Larger sizes are often in stock, and special orders up to 32 inches can be provided quickly.

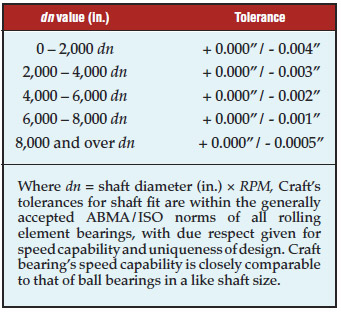

Shaft Size and Tolerance

Craft split bearings are manufactured to tight tolerances, but real-world shaft diameters can vary by a few thousandths of an inch, even along a single shaft. The correct fit becomes especially important at higher loads or speeds.

- Check the journal for diameter, roundness, taper, and straightness.

- Roundness and taper should be within 0.001” along the bearing seat.

- Higher speeds demand tighter shaft tolerances.

A bearing is only as good as the shaft it’s on, so shaft condition directly impacts bearing performance and lifespan.

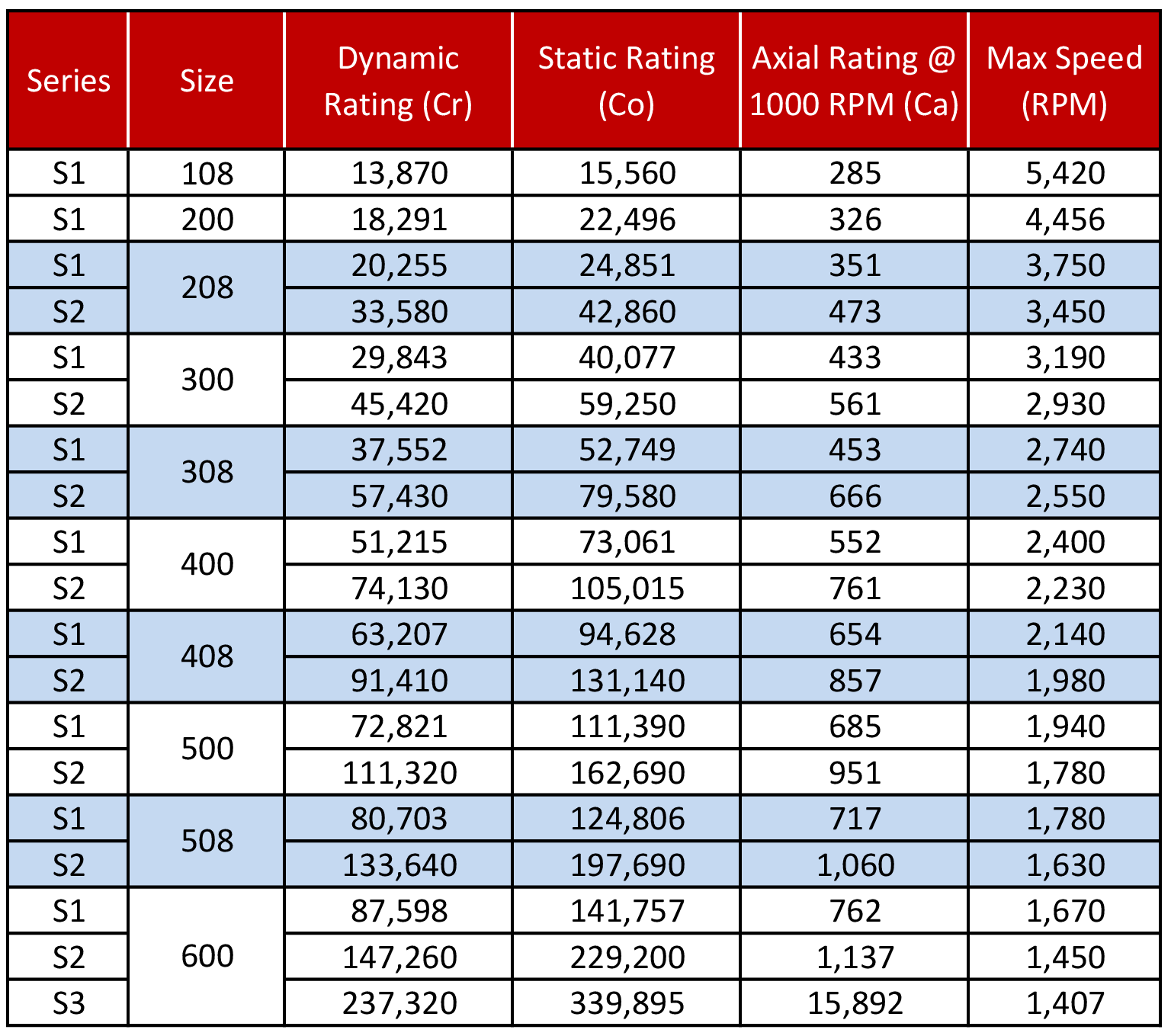

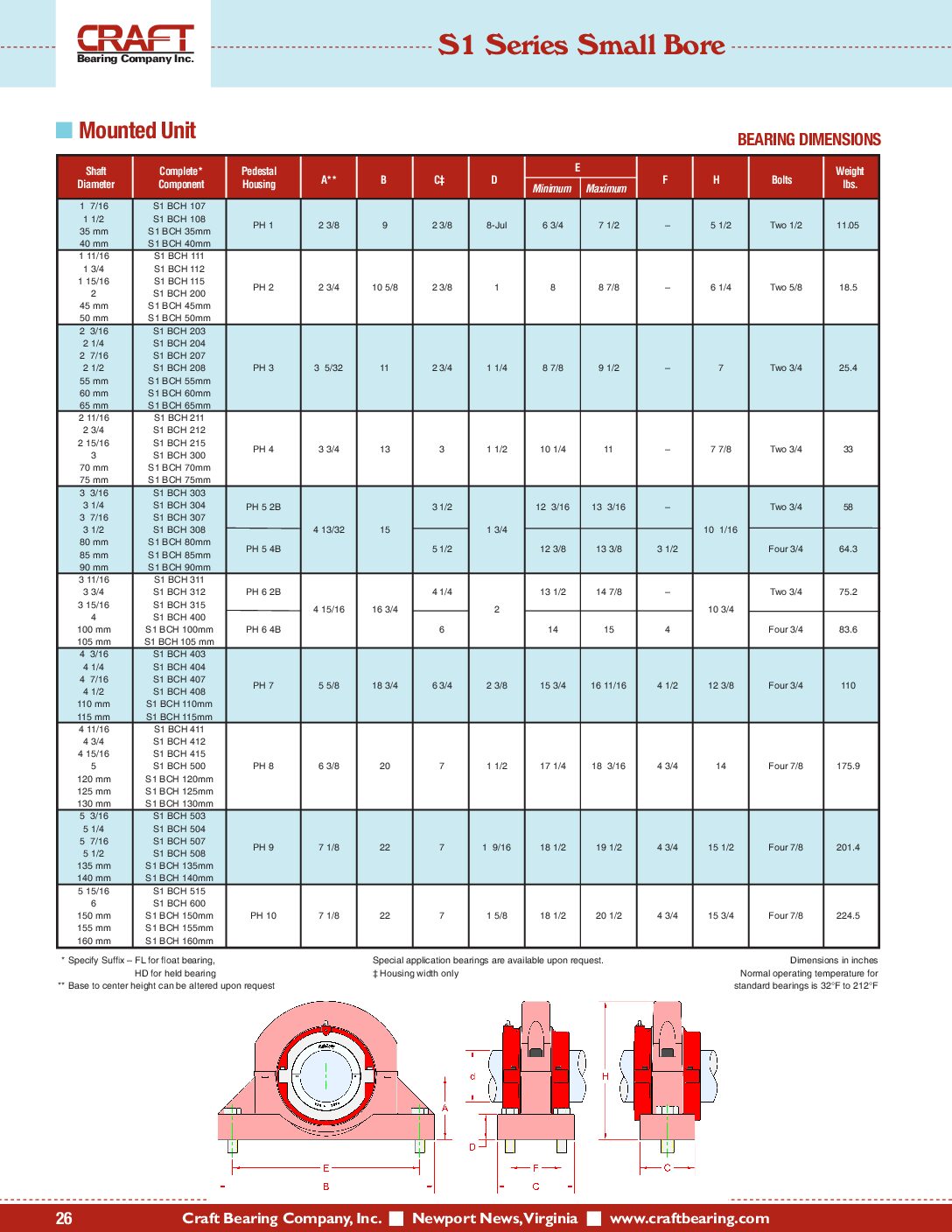

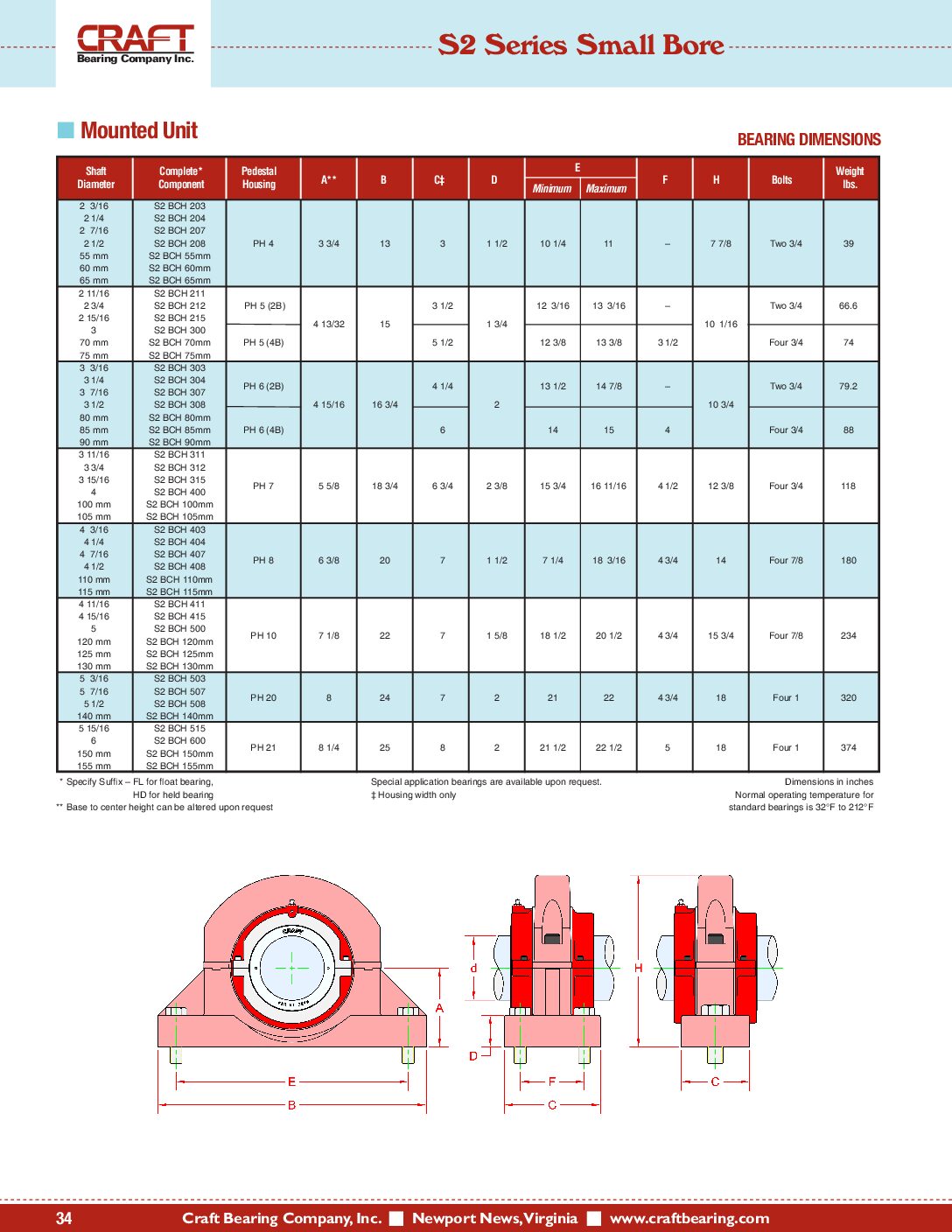

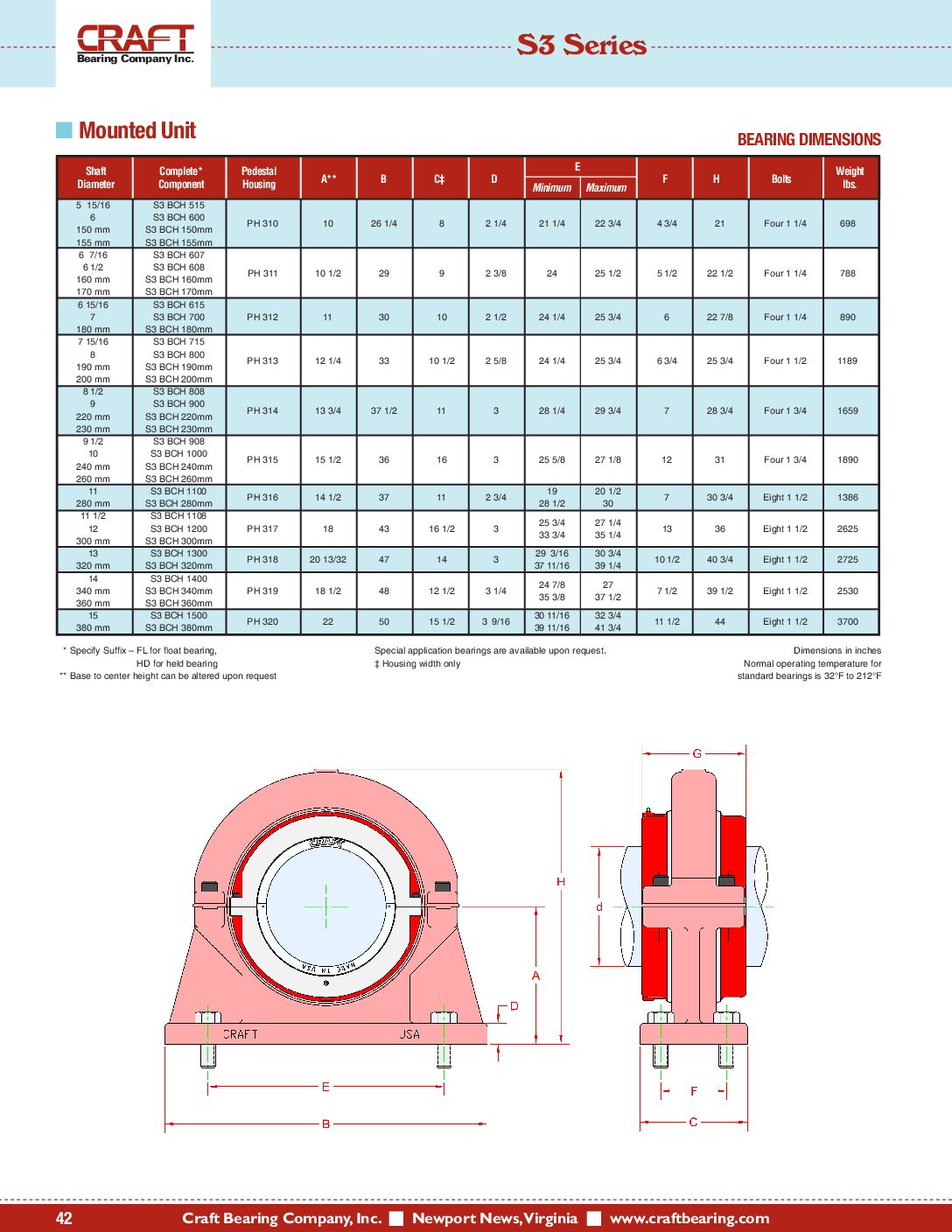

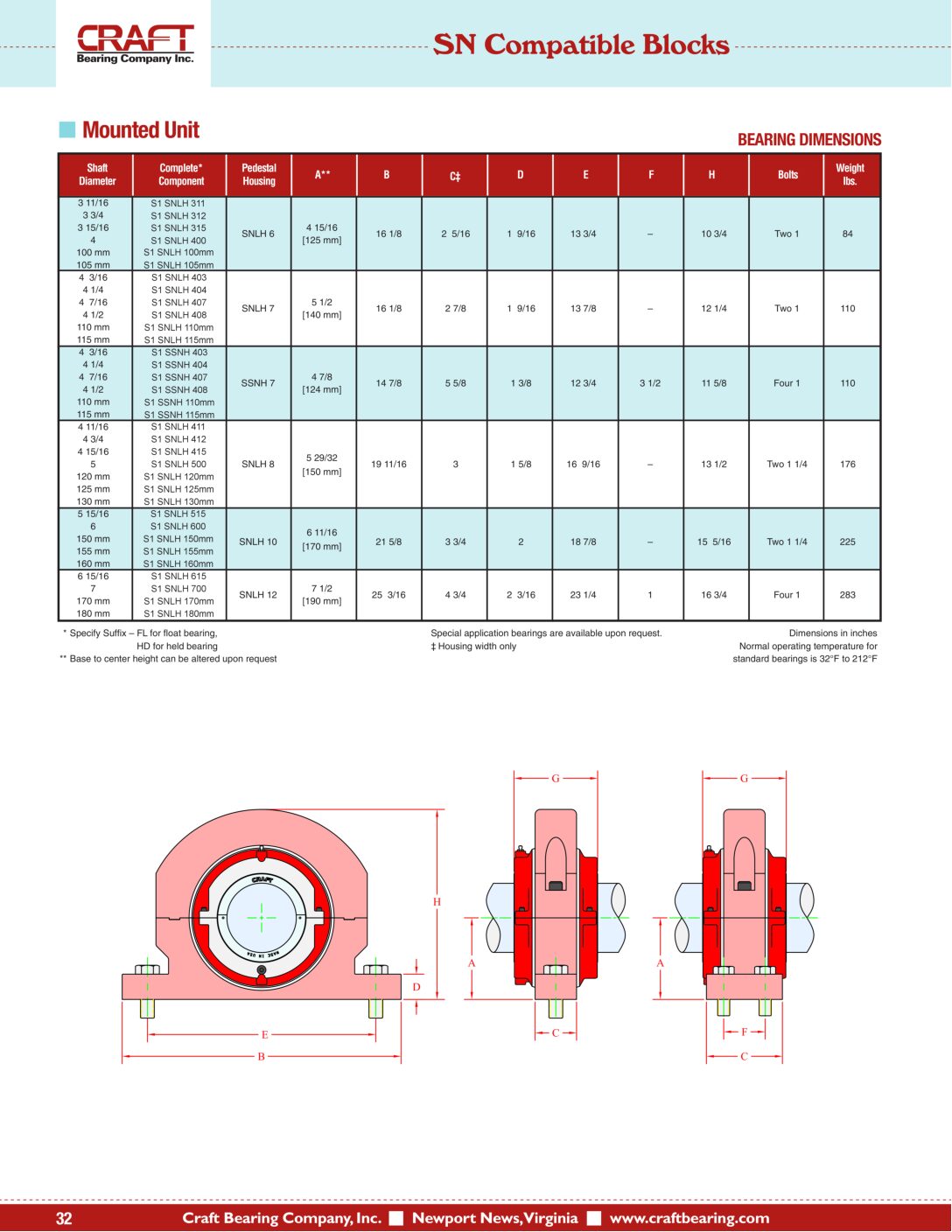

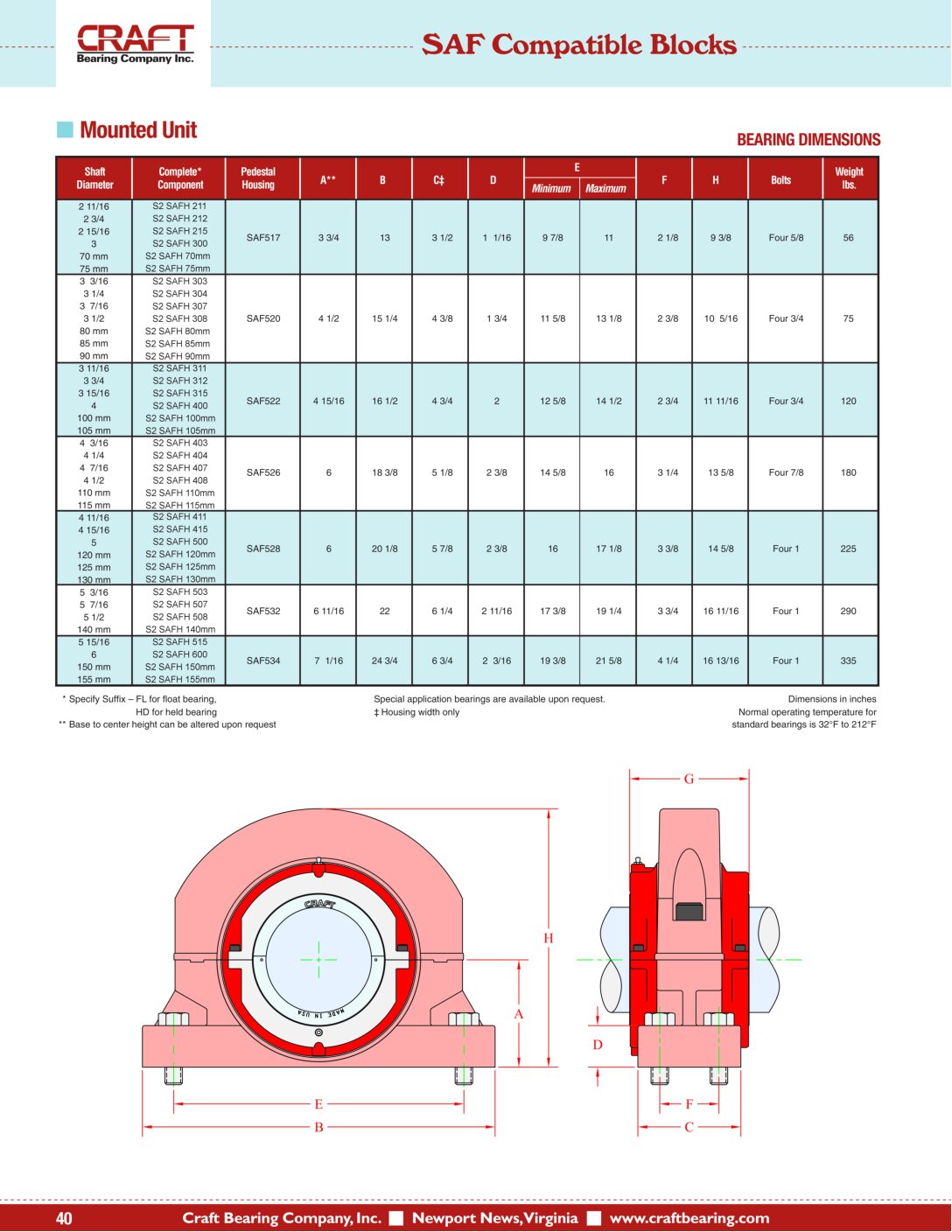

Product Dimensions and Selection

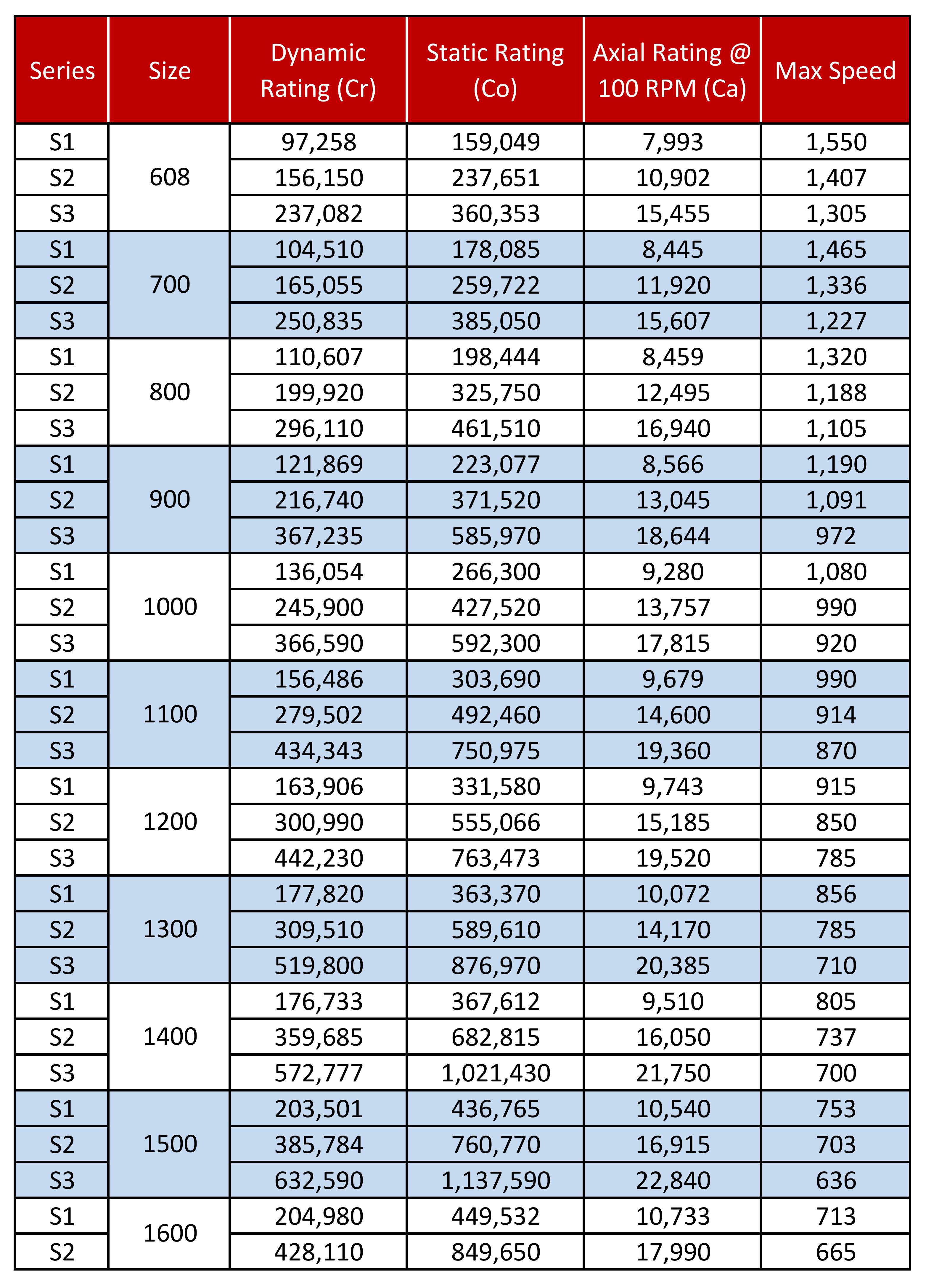

When ordering, know the bearing’s height, width, and length, as well as the load and RPM requirements to select the right series (S1, S2, or S3). The Bearing Dimension section provides dynamic, static, and axial load ratings and maximum speeds for each size and series.

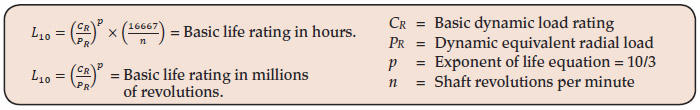

Bearing Life

All load capacity calculations for Craft split bearings comply with ABMA and ISO standards. Bearing life is determined using a fatigue calculation known as the L10 rating, which represents the basic life in hours or millions of revolutions. The L10 is the minimum expected life for 90% of a group of identical bearings. Median life—the point where 50% of bearings reach or exceed the rating—is typically about five times the L10 value.

Quick Reference Load Charts

Small Bore Load Ratings

Large Bore Load Ratings

Quick Reference Dimensions

Click to Download the PDF

S1 Series – Standard Duty

S2 Series – Heavy Duty

S3 Series – Extra Heavy Duty

SN Bearings

SAF Comparable Bearings

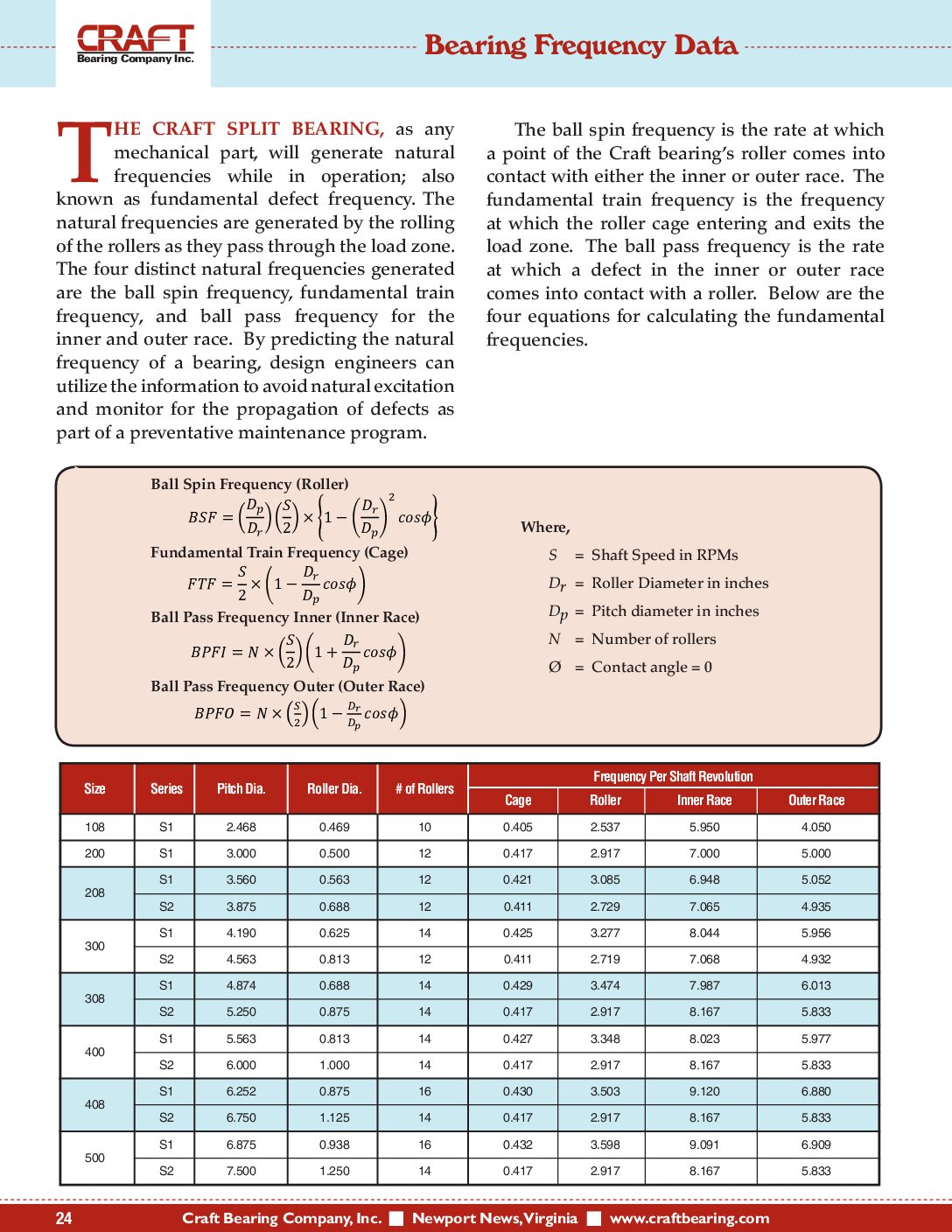

Frequency Data

The Craft Split Bearing, like any mechanical component, generates natural (fundamental defect) frequencies during operation as rollers move through the load zone. Four distinct frequencies occur: the ball spin frequency, the fundamental train frequency, and the ball pass frequencies for both the inner and outer race. Predicting these frequencies helps engineers avoid natural excitation and monitor potential defects as part of a preventative maintenance plan.

- Ball Spin Frequency: The rate at which a specific point on the roller contacts the inner or outer race.

- Fundamental Train Frequency: How often the roller cage enters and exits the load zone.

- Ball Pass Frequency (Inner & Outer Races): How often a race defect contacts a roller.

The file linked below contains the equations to calculate these four frequencies.